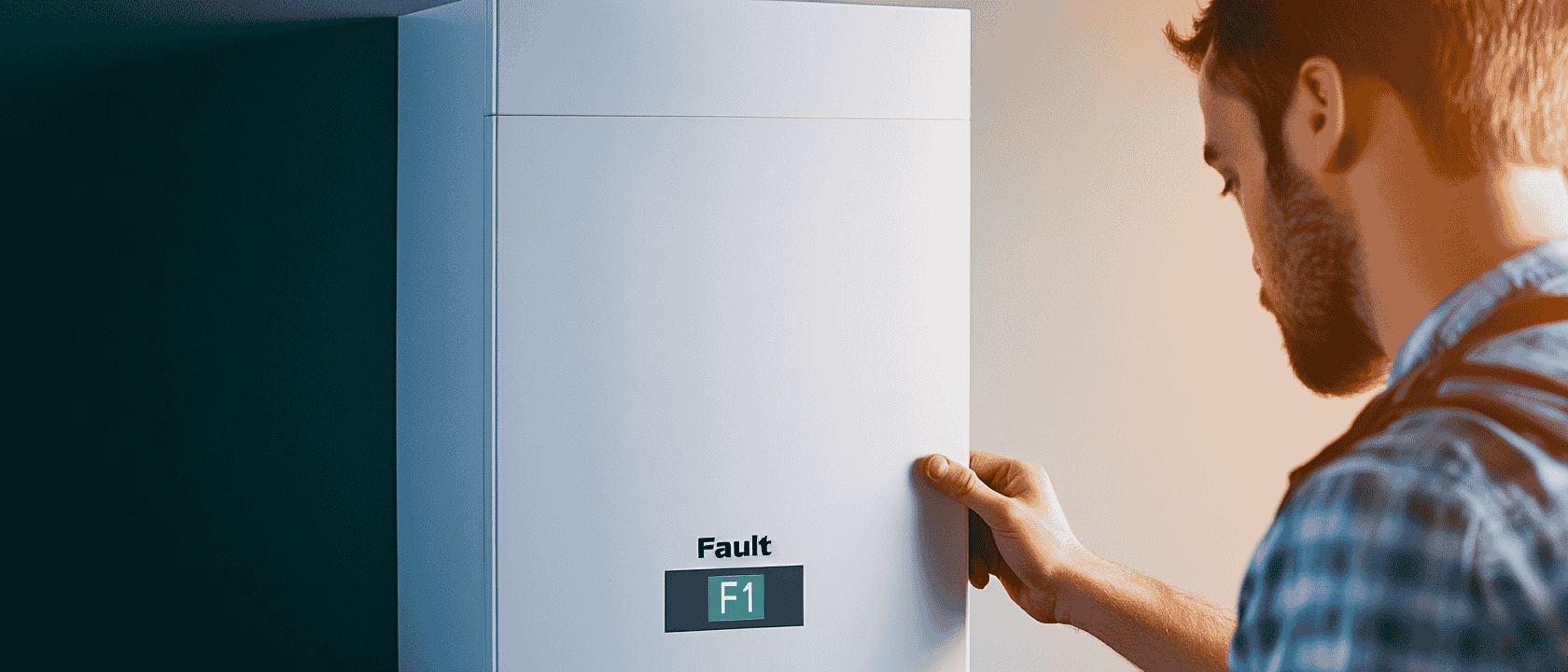

Reasons Behind your F1 Fault Code and how to Rectify it!

Discovering an F1 fault on your boiler indicates low water pressure, a frequent issue in Ideal boilers. This article will explain the F1 fault on boiler systems, explore common causes like leaks and faulty sensors, and guide you through fixing it.

Key Takeaways

- The F1 fault code on Ideal boilers signals low water pressure, which can hinder heating efficiency and may result from leaks or faulty sensors.

- Addressing the F1 error involves checking the pressure gauge, re-pressurising the boiler correctly, and repairing any leaks to maintain optimal performance.

- Regular maintenance, monitoring of boiler pressure, and annual servicing are essential to prevent the F1 error code from reoccurring and ensure the longevity of the boiler.

Understanding the F1 Error Code on Boilers

The F1 fault code is a common sight for many owners of Ideal boilers. This specific boiler error codes is an indicator of low water pressure within the boiler unit, which can significantly impact the efficiency of your central heating system. Modern boilers, including various Ideal boiler models, are equipped with numerous sensors and safety protocols to ensure they operate within safe parameters. When these parameters are breached, such as when the boiler’s water pressure drops too low, the system triggers an error code to alert the user and prevent potential damage.

Knowing what the F1 boiler fault means and why it shuts down your boiler is crucial. This awareness aids in both troubleshooting the issue and maintaining your boiler.

We’ll now explore the specifics of the Fault F1 and why your boiler shuts off when this fault occurs.

What does the F1 error code signify?

The F1 error code on Ideal boilers is a clear signal that the water pressure in your boiler system has fallen below the necessary threshold. Typically, the recommended pressure for an Ideal boiler is between 1 and 1.5 bar. When the pressure drops below this level, it can lead to an ineffective central heating system, with symptoms such as strange noises from radiators and the pressure gauge reading below 1 bar.

Common causes of low boiler pressure that trigger the F1 fault include leaks from loose joints or pinholes and a faulty pressure sensor that provides false readings. If the boiler loses pressure consistently, it may indicate a more severe issue within the heating system that needs addressing before simply adding more water through the filling loop.

Why does the boiler shut off with an F1 fault?

When the F1 boiler fault appears, the boiler’s safety mechanisms kick in to shut down the system. This automatic shutdown is a protective measure designed to prevent further damage or safety hazards caused by operating with low water pressure. Modern boilers are equipped with these safety protocols to ensure that low pressure does not lead to more severe issues, such as overheating or damage to the boiler’s components.

The boiler shuts off to protect itself and alert the owner that immediate attention is needed. This proactive measure safeguards both the boiler and the household’s safety.

Understanding this safety feature highlights the importance of monitoring and maintaining your boiler’s pressure to avoid unexpected shutdowns.

Common Causes of the F1 Error Code

The Code F1 on Ideal boilers including the Ideal Logic boiler is triggered by a variety of underlying issues, all related to insufficient water pressure. Common causes include low pressure within the system, faulty pressure sensors, and leaks in the central heating system. Regular checks and maintenance can help identify these issues before they escalate into a full-blown F1 error.

We’ll delve into the most frequent causes of the F1 boiler fault. Understanding these common issues, from low boiler pressure to faulty sensors and leaks, can help you troubleshoot and resolve the F1 fault more effectively.

Low Boiler Pressure

Low boiler pressure is a primary culprit behind the F1 boiler fault. This issue can arise from various factors, including defects in the pressure relief valve, leaks in the boiler or pipework, trapped air, and corrosion. Usually, the main reason for low boiler pressure is the loss of pressure in the central heating system.

Frequent pressure drops can also result from a leaky heating system or malfunctioning pressure gauge. Consistent pressure loss necessitates investigating and repairing underlying leaks to prevent recurring issues.

Faulty Pressure Sensor

A faulty pressure sensor can mislead the boiler’s control system, triggering the F1 error code. Inaccurate readings from the pressure sensor send false signals to the boiler’s PCB, making the system believe the pressure is too low.

This issue can be particularly challenging to diagnose, as the pressure gauge may display normal readings despite the code F1 appearing. In such cases, it’s advisable to call a professional to inspect and potentially replace the damaged pressure sensor.

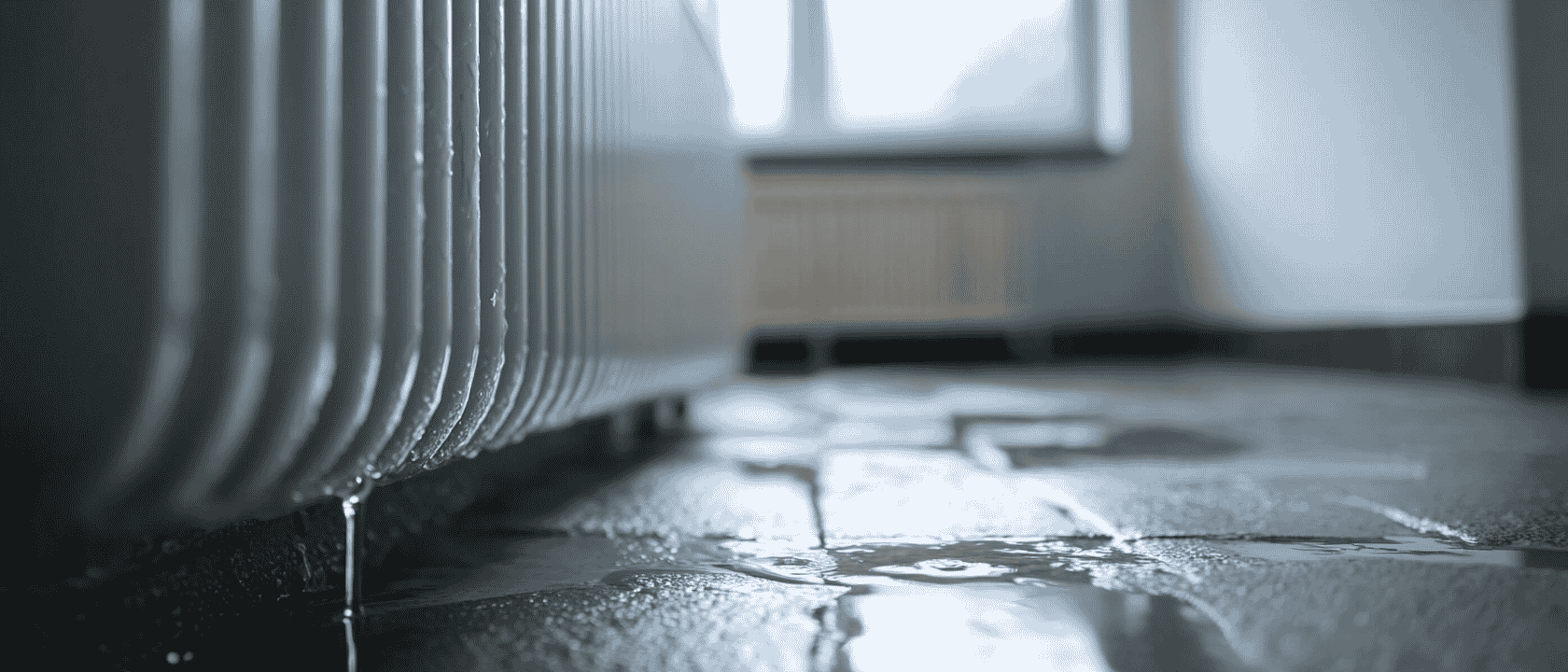

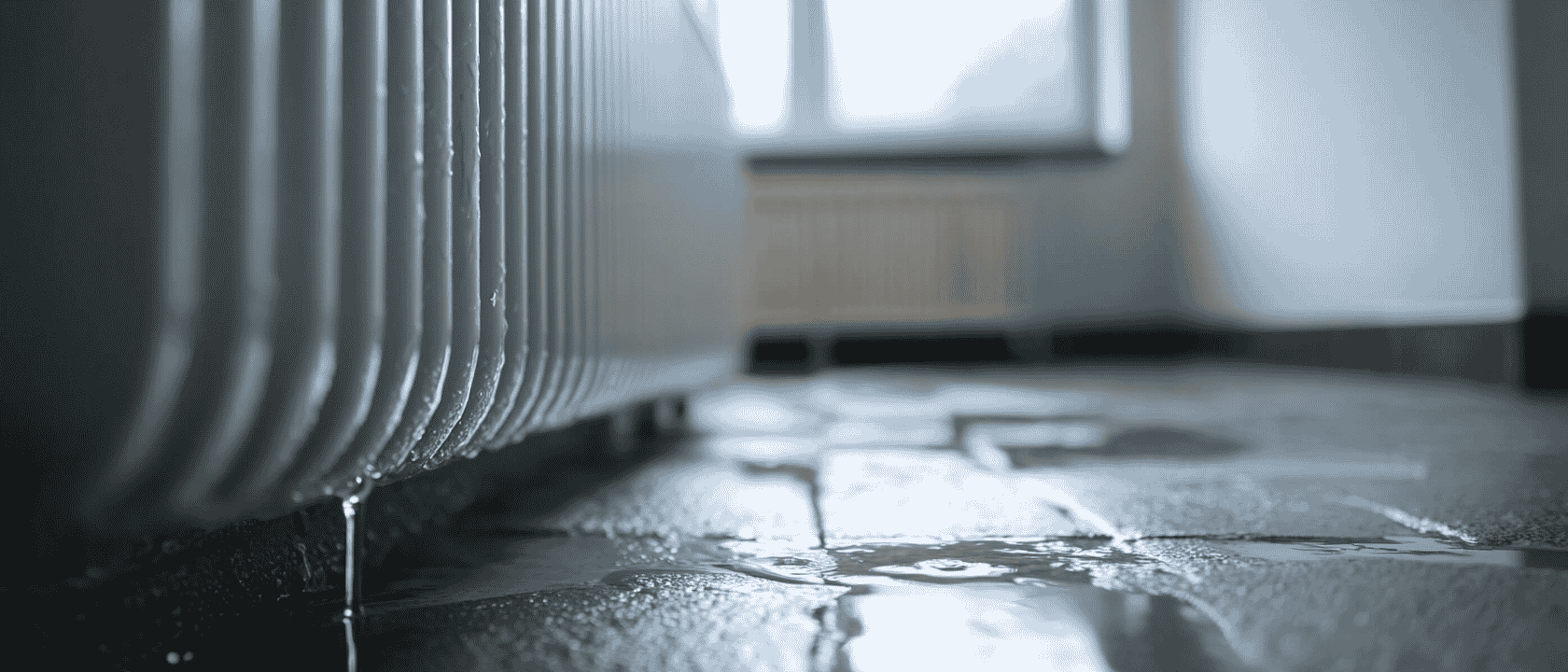

Leaks in the Central Heating System

Leaks in the central heating system are another common cause of the F1 error code. These leaks can be both visible and hidden, with pinholes in towel rails, radiators, and copper pipework often being the culprits. Loose joints and corrosion around boiler components can also lead to significant water loss.

Detecting hidden leaks may require a Gas Safe engineer’s expertise, as these can cause a gradual and persistent drop in boiler pressure. Regular inspections and maintenance help identify and repair such leaks before more severe issues arise.

How to Fix the F1 Fault Code

Fixing the F1 boiler fault involves a few straightforward steps, starting with checking the boiler pressure gauge and repressurising the system if necessary. It’s essential to address any leaks before attempting to increase the boiler’s pressure to ensure a lasting solution.

Here, we’ll provide detailed instructions on checking the pressure gauge, using the filling loop to repressurise the boiler, and repairing leaks to resolve the F1 boiler fault effectively.

Checking the Boiler Pressure Gauge

The first step in troubleshooting the code F1 is to check the boiler’s pressure gauge. This gauge is crucial for determining if the boiler’s pressure is within the required range for normal operation. Regularly monitoring the pressure gauge can help you identify if the pressure is too low and diagnose the F1 error early.

A reading below 1 bar on the pressure gauge indicates insufficient boiler pressure and needs topping up. This initial check is vital for ensuring the boiler’s efficient operation and preventing further issues.

Repressurising the Boiler using the Filling Loop

If the pressure is too low, the next step is to repressurise the boiler using the filling loop. This process involves opening a valve to allow water into the heating system, thus restoring the pressure to the recommended level. It’s essential to follow the manufacturer’s instructions carefully when using the filling loop to avoid overpressurising the system.

Once the boiler pressure is back within the normal range, you can restart the boiler and check if the F1 fault code has cleared. Regularly checking and repressurising the boiler ensures efficient operation and reduces the likelihood of recurring F1 errors.

Repairing Leaks

Repairing leaks is crucial to resolving the F1 boiler fault. Inspect towel rails, radiators, copper pipework, and loose joints for any signs of water loss. Look for obvious indicators like dripping water or dampness around the system.

If you find any leaks, contact a Gas Safe engineer to perform the repairs. Professional repair ensures leaks are fixed correctly, preventing further pressure drops and recurring F1 faults.

Preventing Future F1 Errors

Preventing future F1 errors involves regular maintenance and monitoring of your boiler system. By keeping your boiler in top condition, you can avoid the common causes of low pressure and the F1 boiler fault. Regular boiler servicing and inspections can uncover potential issues before they escalate.

We’ll discuss essential preventive measures, including regular maintenance, monitoring boiler pressure, and scheduling annual servicing.

Regular Boiler Maintenance

Regular boiler maintenance is key to preventing the F1 boiler fault. Routine inspections by a Gas Safe engineer ensure potential issues are addressed promptly. This proactive approach helps the central heating system operate efficiently and reduces the likelihood of encountering the F1 error.

Routine maintenance by qualified professionals is crucial for the boiler’s longevity and optimal performance and is essential in avoiding an untimely breakdown requiring an urgent boiler repair. Regular checks and servicing can prevent costly repairs and ensure the boiler operates within the normal range.

Monitoring Boiler Pressure

Regularly monitoring the boiler pressure gauge is another effective preventive measure. Frequent inspections help identify pressure drops early, allowing for corrective action before the F1 error code appears.

Monitoring the boiler’s pressure gauge ensures the boiler operates within safe pressure limits, preventing unexpected shutdowns and maintaining an efficient heating system.

Annual Servicing

Annual servicing by a qualified Gas Safe local plumber is crucial for maintaining boiler efficiency and safety. Regular servicing helps identify potential issues before they lead to faults like the F1 error code. This preventive measure ensures the boiler functions effectively and extends its lifespan.

When to Call a Professional

While some boiler issues can be resolved with basic troubleshooting, persistent F1 errors and complex repairs require professional intervention. Knowing when to call a qualified engineer can save you from costly repairs and ensure the boiler is fixed correctly.

We’ll outline scenarios that necessitate professional help, including persistent F1 errors and complex repairs involving internal components.

Persistent F1 Errors

If the F1 error persists despite your troubleshooting efforts, consult a qualified Gas Safe engineer. Persistent errors may indicate underlying issues needing professional diagnosis and repair. Ignoring the F1 error code can lead to significant problems, potentially necessitating the replacement of the entire boiler.

If you suspect a leak or the pressure gauge reads normally but the F1 error remains, contact a Gas Safe heating engineer for a thorough inspection. Promptly addressing persistent F1 faults can prevent further damage and ensure efficient boiler operation.

Complex Repairs

Complex repairs involving internal components or electrical parts of the boiler should always be handled by a professional. Attempting these repairs without the appropriate expertise can cause further damage or safety hazards. A Gas Safe engineer is trained to handle such repairs safely and in compliance with regulations.

Prioritising safety and professional expertise ensures the boiler is repaired correctly and operates within the recommended parameters. This approach prevents costly repairs and maintains the boiler’s efficiency and longevity.

Summary

In summary, the F1 fault code on your Ideal boiler is a crucial indicator of low water pressure that requires immediate attention. Understanding this error code, its common causes, and how to fix it can save you from unexpected cold days and the need of an emergency plumber. Regular maintenance, monitoring boiler pressure, and annual servicing are key to preventing future F1 errors and ensuring your boiler operates efficiently.

Remember, while some issues can be resolved with basic troubleshooting, persistent errors and complex repairs should be left to professionals. By taking these preventive measures and knowing when to call a qualified engineer, you can keep your boiler running smoothly and your home warm and cozy all year round.

Frequently Asked Questions

What does the F1 error code on my Ideal boiler mean?

The F1 error code on your Ideal boiler means there’s low water pressure, which can hinder your heating system’s efficiency and potentially cause damage if not fixed. It’s essential to check and replenish the water pressure to keep everything running smoothly.

How can I fix the F1 fault code on my boiler?

To fix the boiler fault code on your boiler, start by checking the pressure gauge; if it’s below 1 bar, use the filling loop to repressurise it. Don’t forget to check for any leaks in the system, as those need to be fixed first!

Why does my boiler shut down when the F1 fault code appears?

When your boiler shows the F1 boiler fault, it shuts down to protect itself from potential damage caused by low water pressure. This safety feature is crucial for your home’s safety and the boiler’s longevity.

What are the common causes of the F1 error code?

The F1 error code often pops up due to low boiler pressure, faulty pressure sensors, or leaks in your heating system. Keeping up with regular maintenance can help catch these problems early!

When should I call a professional to fix the F1 fault code?

If the F1 code keeps showing up despite your troubleshooting, or if you think there’s a leak or complicated repairs needed, it’s time to call in a qualified Gas Safe engineer. At Homecure Plumbers in London we are well versed with repairing the F1 fault and are available to help should you need us! give us a call today.

Available 24/7, 365 days

City & Guilds trained plumbers

Friendly and helpful service

Fully qualified and insured engineers

Available round the clock support

Ability to deal with any brand or type

Reach us 24/7, 365 days

We’ll get to you within an hour

Repair and install a variety of heating systems