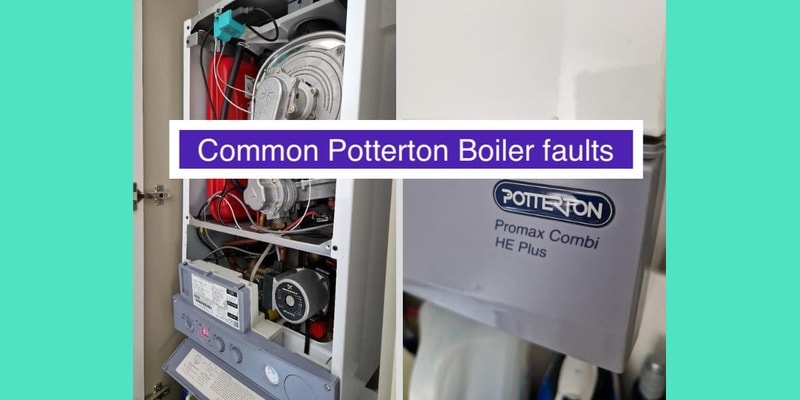

Potterton fault codes and fixes, your comprehensive guide!

Dealing with a Potterton boiler fault? This article will help you identify common problems like low pressure, no hot water, and various error codes. Learn DIY fixes and discover when it’s best to call a professional. Get your boiler running smoothly again.

Key Takeaways

- Common issues with Potterton boilers include low pressure, lack of hot water, and frozen condensate pipes, which can often be resolved with DIY fixes.

- Understanding Potterton boiler error codes is crucial for diagnosing issues and knowing when to seek professional help.

- Deciding to repair or replace a boiler involves evaluating costs, efficiency, and the age of the unit, with newer models offering significant long-term savings.

Frequent Potterton Boiler Faults

Boilers, like any complex system, can develop certain issues, particularly as they age. Common problems include low boiler pressure, no hot water, frozen condensate pipes, and faulty diverter valves. These issues can disrupt your heating system, leaving you without warmth when you need it most. Recognising these problems is crucial for effective troubleshooting.

Low Boiler Pressure

Low boiler pressure is a common issue with boilers and can significantly impact their efficiency. Error code E119 indicates this problem, showing that the system pressure is too low. Common causes include leaks, broken seals, or pinholes in radiators, which can gradually reduce the pressure.

If you notice that the pressure gauge needle is below 1, it’s a sign that your boiler’s pressure is too low. This issue can often be resolved by checking the primary system water pressure and adding more water to the system.

Understanding how to diagnose and fix low boiler pressure can save you from unnecessary service calls.

DIY Fix for Low Pressure

Re-pressurising your boiler is typically a straightforward task. The filling loop, usually located under the boiler, is used to add water and increase system pressure. Consult the user manual for specific instructions related to your model before starting.

Once you’ve identified the filling loop, connect it and gradually add water while watching the pressure gauge. Aim to bring the needle to the recommended range, usually between 1 and 1.5 bars. After re-pressurising, ensure all valves are properly closed to prevent leaks.

No Hot Water from Boiler

Lack of hot water is another common issue with boilers, especially frustrating during colder months. This problem often results from a faulty diverter valve or diverter valve microswitch, which controls the flow of hot water between the heating system and your taps. If these components fail, you might have an operational heating system but no hot water.

Gas valve malfunctions are another culprit. These valves regulate gas flow to the boiler, and if they fail, it can prevent the boiler from igniting or cause it to shut down unexpectedly. Persistent issues may require professional consultation to avoid potential safety hazards.

DIY Fix for No Hot Water

If your boiler isn’t providing hot water, there are several DIY steps you can take before calling professionals. Start by checking the pressure gauge; if it’s below 1 bar, re-pressurising the system might solve the problem. Another common winter issue is a frozen condensate pipe. Carefully thawing the pipe with warm water can help restore hot water flow.

Ensure that your gas supply is intact by checking other gas appliances in your home. If the gas supply is functioning correctly and the boiler still isn’t producing hot water, more in-depth troubleshooting or professional assistance may be needed.

Error Codes in Potterton Boilers

Potterton boilers come with various potterton boiler error codes to help diagnose issues quickly and efficiently. Understanding these codes is key for effective potterton boiler troubleshooting and can save time and guesswork. Each error code corresponds to a specific fault within the boiler, indicating issues with sensors, pressure, or ignition.

For instance, faults in sensors like the Domestic Hot Water (DHW) NTC sensor or the central heating thermistor can trigger error codes that disrupt your heating and hot water supply, including a temperature coefficient ntc fault and a wiring fault. Understanding what each code means can help you decide whether you can fix the issue yourself or if it requires professional attention.

Potterton Boiler Error Codes list

Understanding the various Potterton boiler error codes that display is essential for diagnosing and resolving issues. Here is a list of common error codes and what they signify:

- E10 Outdoor sensor issue

- E20 code indicates a fault with the central heating thermistor sensor.

- E28 Flue thermistor fault

- E50 There is a fault with the domestic hot water sensor.

- E110 Boiler overheat

- E119 The system is experiencing low pressure

- E125 The issue identified is a primary water circulation fault

- E130 Flue thermostat tripped

- E131 Flue overheat lockout

- E133 Ignition fault

- E151 indicates that there is an error with the printed circuit board (PCB).

- E152 PCB fault

- E160: Fan fault

- E161 Fan fault DHW fault

- E164 DHW sensor fault (domestic hot water sensor) Could be heating flow sensor

- E167 PCB fault

- E168 PCB lockout

- E193 Circulation issues

Common Potterton Boiler Error Codes

Among the numerous fault codes, some are more common and need immediate attention. Error E110 indicates that the boiler has overheated and requires prompt action to prevent further damage. Error E133, another frequent issue, signifies an ignition fault that can prevent the boiler from starting.

When the boiler locks out and displays error code E133, it often indicates a frozen condensate pipe, especially during winter. Before panicking, check the gas supply as a fundamental step in troubleshooting these codes.

When to Call a Professional

Knowing when to call a professional can prevent potential hazards and further complications. If your boiler continues to show error codes after basic troubleshooting, consult a Gas Safe Engineer who can carry out boiler repairs. Persistent issues, like no hot water despite your efforts, might indicate a deeper problem.

For instance, gas valve malfunctions pose significant safety risks and should be addressed by qualified professionals immediately. Recognising the limits of DIY fixes is crucial for maintaining the safety and efficiency of your boiler.

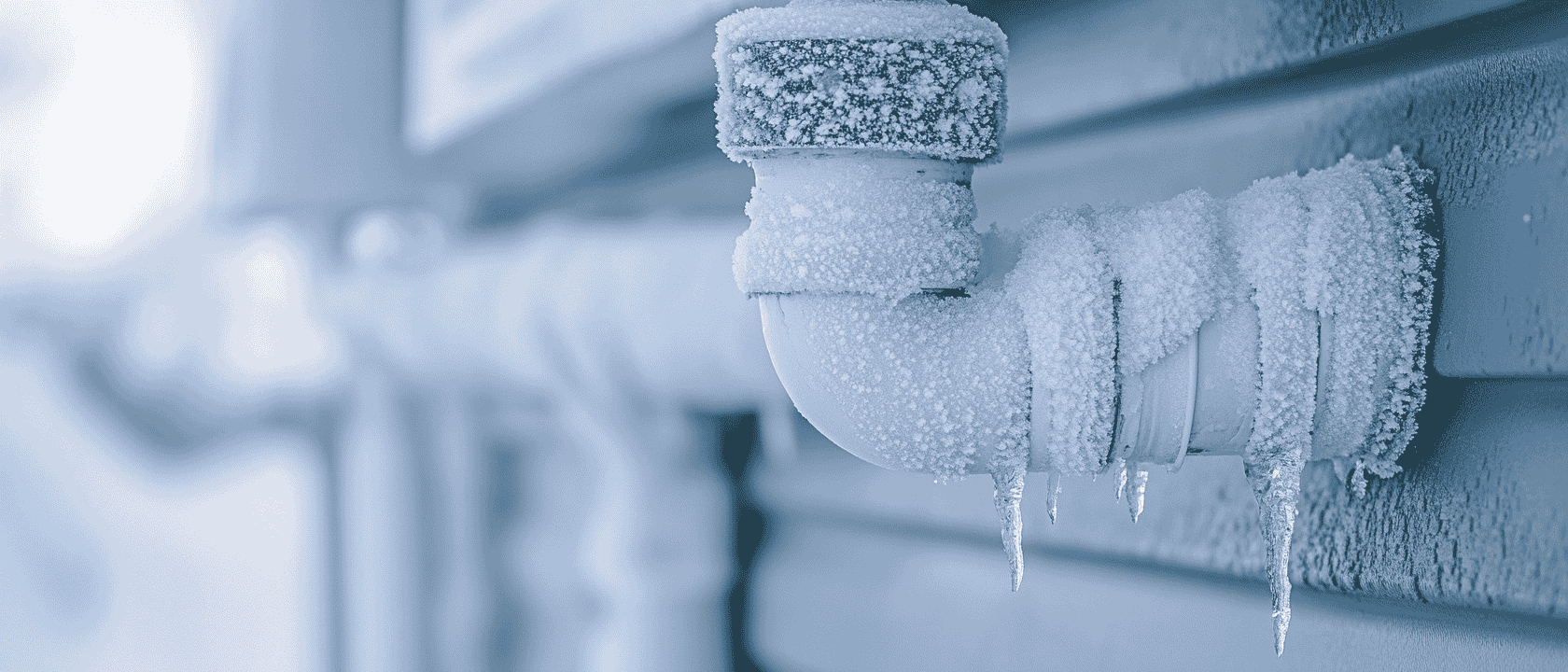

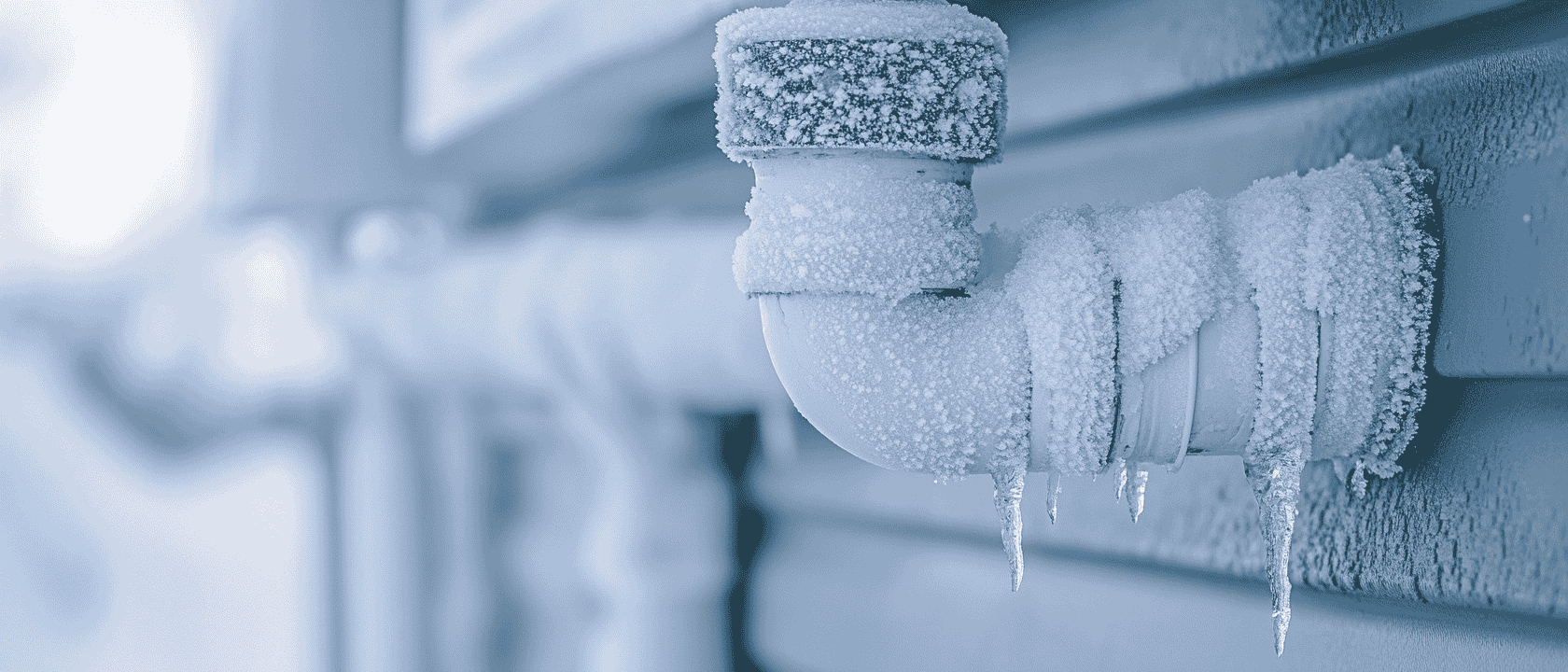

Winter-Specific Issues

Winter presents unique challenges for boilers, with frozen condensate pipes being a common issue. When temperatures drop, the water in the condensate pipe can freeze and create a blockage, causing the boiler to lock out. This is inconvenient and can lead to potential damage if not addressed promptly.

Cold weather can significantly impact heating systems, and knowing how to address these issues can prevent a small problem from becoming a major one. Here are the specifics of frozen condensate pipes and how to handle them.

Frozen Condensate Pipes

When a condensate pipe freezes, it creates a blockage that forces the boiler to shut down as a protective measure to prevent flooding. The boiler typically displays the E133 error code to indicate this freezing issue. This common problem during colder months can significantly impact your Potterton boiler’s functionality.

Addressing a frozen condensate pipe involves carefully thawing the blockage to restore normal operation. Properly insulating the pipe can help prevent future occurrences.

Thawing and Preventing Freezing

Thawing a frozen condensate pipe can be done using warm water, a hairdryer, or a hot water bottle. Apply these methods with caution to avoid damaging the pipe. Once thawed, check the boiler to ensure it resumes normal operation.

To prevent pipes from freezing again, consider insulating them, especially those exposed to harsh winter conditions. Regular maintenance and checks during winter can help avoid this issue altogether.

Radiator and Heating System Problems

Radiator and heating system issues can significantly impact the overall efficiency of your central heating system. Common problems include radiators not heating evenly due to trapped air or sludge build-up. These issues can lead to cold spots and reduce the effectiveness of your heating system.

Addressing these problems promptly can improve heating efficiency and ensure a warm, comfortable home during the cold months. Here are some common radiator issues and how to fix them.

Radiators Not Heating Evenly

Uneven heating in radiators often means there is trapped air or sludge obstructing the hot water flow. Cold spots in radiators indicate that air is restricting hot water flow, causing inconsistent heating. Over time, sludge can accumulate due to water stagnation and metallic debris, worsening the issue.

If bleeding the radiators does not resolve cold spots, it might indicate a more serious problem, such as sludge build-up, which requires a more thorough approach by a heating engineer.

Bleeding Radiators

Bleeding radiators is a simple DIY task that can greatly improve heating system efficiency. This process involves releasing trapped air to allow hot water to flow freely through the radiator.

To start, turn off the heating and let the system cool. Use a radiator key to open the bleed valve. Once you hear a hissing sound, air is escaping. Close the valve once water starts to come out and check the pressure gauge on your boiler to ensure the system pressure is within the recommended range.

Sludge and System Flushing

Sludge build-up in radiators is a common issue that can greatly affect heating system efficiency. This sludge, composed of metallic debris and stagnant water, can accumulate over time and block hot water flow. When sludge accumulates, it restricts water flow, leading to uneven heating and reduced system efficiency.

Power flushing is an effective method to remove sludge from your heating system. This process uses high-pressure water and chemicals to break up and flush out sludge, improving heat distribution and overall system performance.

Regular maintenance like doing an annual boiler service and system flushing can prevent sludge build-up and keep your heating system running smoothly.

Advanced Boiler Faults

Some boiler issues are more complex and require specialised knowledge for diagnosis and repair. Advanced faults such as problems with the printed circuit board (PCB), gas valve issues, and faulty sensors often necessitate the expertise of a Gas Safe Engineer. These complex issues can disrupt boiler operations and pose safety risks if not addressed properly.

When error codes persist after basic troubleshooting, it’s crucial to seek professional help to ensure the safety and functionality of your boiler. Let’s delve into some of these advanced faults and understand why professional intervention is necessary.

Printed Circuit Board (PCB) Issues

The printed circuit board (PCB) is a critical component of your boiler, controlling its various functions. Faults in the PCB can lead to irregular boiler operation and a range of operational failures. Error codes such as E151 often indicate PCB issues, which require professional evaluation and repair.

A malfunctioning PCB can prevent the boiler from operating correctly, leading to frequent shutdowns or failure to ignite. Given the complexity of PCB repairs, it’s essential to have a qualified technician handle this issue to ensure safety and proper functionality.

Gas Valve Problems

Gas valves regulate the flow of gas to your boiler, and any malfunction can pose significant safety risks, including gas leaks. Error codes related to gas valve issues are serious and should prompt immediate professional intervention.

Gas valve malfunctions can prevent the boiler from igniting or cause it to shut down unexpectedly, disrupting your heating and hot water supply. Addressing these issues promptly with the help of a Gas Safe Engineer is crucial to ensure the safety and efficiency of your boiler.

Sensor Faults

Sensors play a crucial role in the operation of your Potterton boiler, regulating various functions such as heating and hot water delivery. Faults in sensors like the Domestic Hot Water (DHW) NTC sensor fault can lead to disruptions in boiler performance. Error codes related to a sensor fault indicate that these components may need replacement to restore proper functionality.

For example, error codes indicating issues with the central heating thermistor sensor or the DHW NTC sensor require professional assessment and repair. Ensuring these sensors are functioning correctly is vital for the overall performance and safety of your boiler.

Deciding on Boiler Replacement

Deciding whether to repair or replace your boiler can be challenging. Factors such as the age of your Potterton boiler, its efficiency, and the frequency of repairs should all be considered. Older boilers tend to consume more energy and may not be as efficient as newer models.

If repair costs are escalating and your boiler is frequently breaking down, it might be more economical to invest in a new boiler. Assessing these factors can help you make an informed decision that balances cost and efficiency.

Cost-Benefit Analysis

The cost of ongoing repairs can add up quickly, making a replacement boiler a more economical choice in the long run. Newer Potterton boilers and tank boiler systems are designed to be more energy-efficient, which can result in significant savings on your energy bills.

Investing in a new boiler might seem like a hefty upfront cost, but the long-term savings and peace of mind can be well worth it. Conducting a thorough cost-benefit analysis can help you determine whether it’s time to replace your old boiler with a more efficient model.

Warranty and Efficiency Benefits

New Potterton boilers come with extended warranties that offer better coverage compared to older models, providing financial protection and peace of mind. Additionally, replacing an old G-rated boiler with a modern A-rated one can save you up to £315 a year on energy bills.

These newer models are not only more efficient but also come with features that enhance their performance and longevity. When considering a boiler replacement, the benefits of improved efficiency and extended warranty coverage make a compelling case for investing in a new system.

Summary

Understanding common Potterton boiler faults and how to address them can save you time, money, and a lot of frustration. From low boiler pressure to more complex issues like PCB and gas valve problems, knowing what to look for and when to call a professional is crucial. Regular maintenance and timely interventions can keep your boiler running efficiently and safely.

In conclusion, whether you’re tackling a DIY fix or deciding on a boiler replacement, being informed and proactive is key. Stay warm and safe this winter by keeping your heating system in top shape, and don’t hesitate to seek professional help when needed.

Frequently Asked Questions

What does the error code E119 mean on my Potterton boiler?

The E119 error code on your Potterton boiler means that the system pressure is too low. Check the pressure gauge and re-pressurise the boiler if needed. Double check the error codes are gone!

How can I fix low boiler pressure myself?

To fix low boiler pressure, you can re-pressurise your system using the filling loop, following the specific instructions in your user manual. This is a straightforward process that can help restore the fault code and your boiler’s functionality.

Why is there no hot water coming from my boiler?

No hot water from your boiler may result from a faulty diverter valve, gas valve issues, or a frozen condensate pipe. It’s advisable to inspect these components to determine the cause.

What should I do if my boiler’s condensate pipe is frozen?

If your boiler’s condensate pipe is frozen, carefully thaw it using warm water, a hairdryer, or a hot water bottle. Ensure you avoid any potential damage during the thawing process.

When should I consider replacing my boiler?

You should consider replacing your boiler if it is ageing, inefficient, and requires frequent repairs, as a new model could save you money in the long run.

Available 24/7, 365 days

City & Guilds trained plumbers

Friendly and helpful service

Fully qualified and insured engineers

Available round the clock support

Ability to deal with any brand or type

Reach us 24/7, 365 days

We’ll get to you within an hour

Repair and install a variety of heating systems