Are you dealing with Baxi boiler issues like low pressure, frozen pipes, or water leaks? This article will walk you through the most common problems and their solutions. From understanding error codes to diagnosing ignition issues, you’ll find the information you need to keep your boiler running smoothly.

Key Takeaways

- Regular maintenance and monitoring of common issues like low boiler pressure, frozen condensate pipes, and water leaks can help maintain the efficiency and longevity of Baxi boilers.

- Troubleshooting ignition problems, such as malfunctioning gas valves or closed gas stopcocks, can prevent heating disruptions and ensure safe boiler operation.

- Understanding Baxi boiler error codes and addressing persistent problems and safety concerns with the help of a Gas Safe registered engineer is crucial for the safe and efficient functioning of the boiler.

Common Baxi Boiler Issues

Baxi boilers, like any other household appliance, can encounter problems over time. These issues can range from minor inconveniences to significant disruptions in your heating and hot water supply. By identifying the common issues with Baxi boilers and learning the respective solutions, you can save considerable time and money, while also reducing frustration.

Error codes and fault lights are vital tools in diagnosing boiler issues. They help pinpoint the exact problem, allowing for quicker and more effective solutions. The comprehension of these codes and their meanings plays a key role in preserving the health, efficiency, and safety of your Baxi boiler.

Typical issues you may face include low boiler pressure, frozen condensate pipes, and water leaks. Each of these problems has its own set of symptoms and solutions, which we’ll explore in detail. Understanding these common issues will help you keep your boiler in peak condition and ensure your home remains warm and comfortable.

Low Boiler Pressure

One of the most common issues with Baxi boilers is low boiler pressure. The normal operating pressure for a Baxi boiler should be between 1.0 and 2.0 bar, with the ideal pressure gauge reading around 1.5 bar when the boiler is cold. If the pressure gauge needle drops below 1.0 bar, your boiler may struggle to provide heat and hot water.

Low boiler pressure can result from various factors, including leaks in the system or faulty components like the pressure relief valve or expansion vessel. Over time, these components can wear out or become damaged, leading to a gradual loss of pressure. Regularly monitoring your boiler’s pressure gauge and promptly managing any pressure drops is vital in preventing more serious issues.

Repressurising your Baxi boiler is a task you can often do yourself by following a few simple steps. However, if you’re unsure or uncomfortable doing this, it’s always best to contact a heating engineer for assistance. Regular maintenance and timely repairs can help keep your boiler running efficiently and prevent more significant problems down the line.

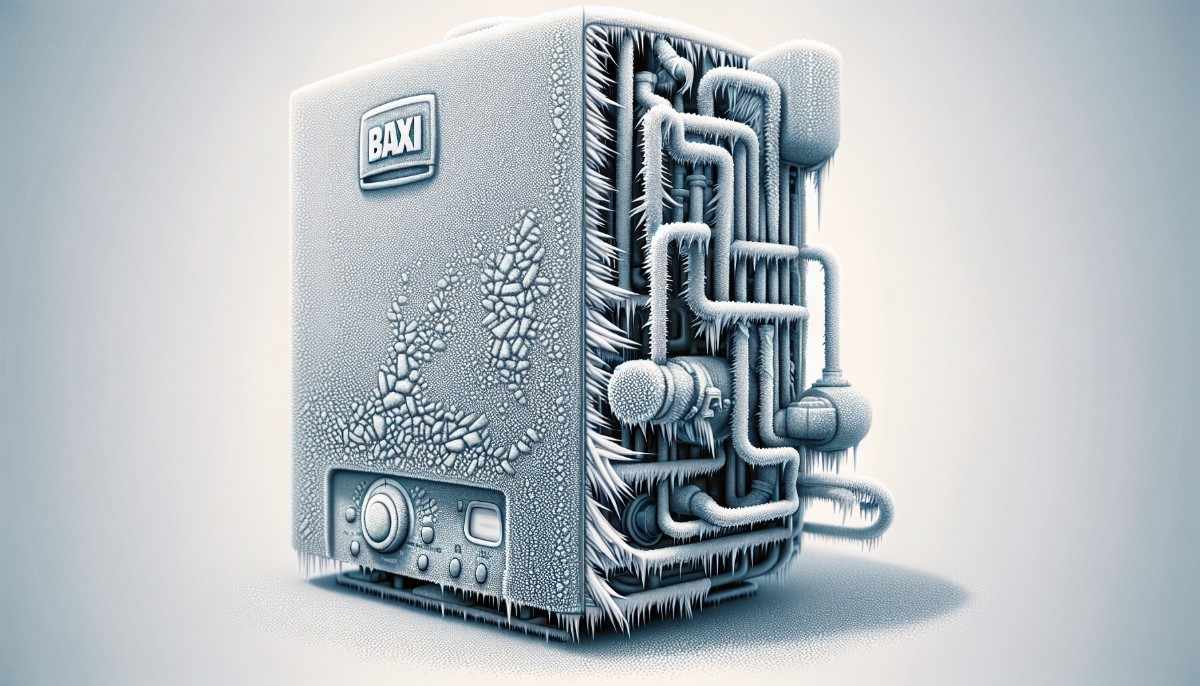

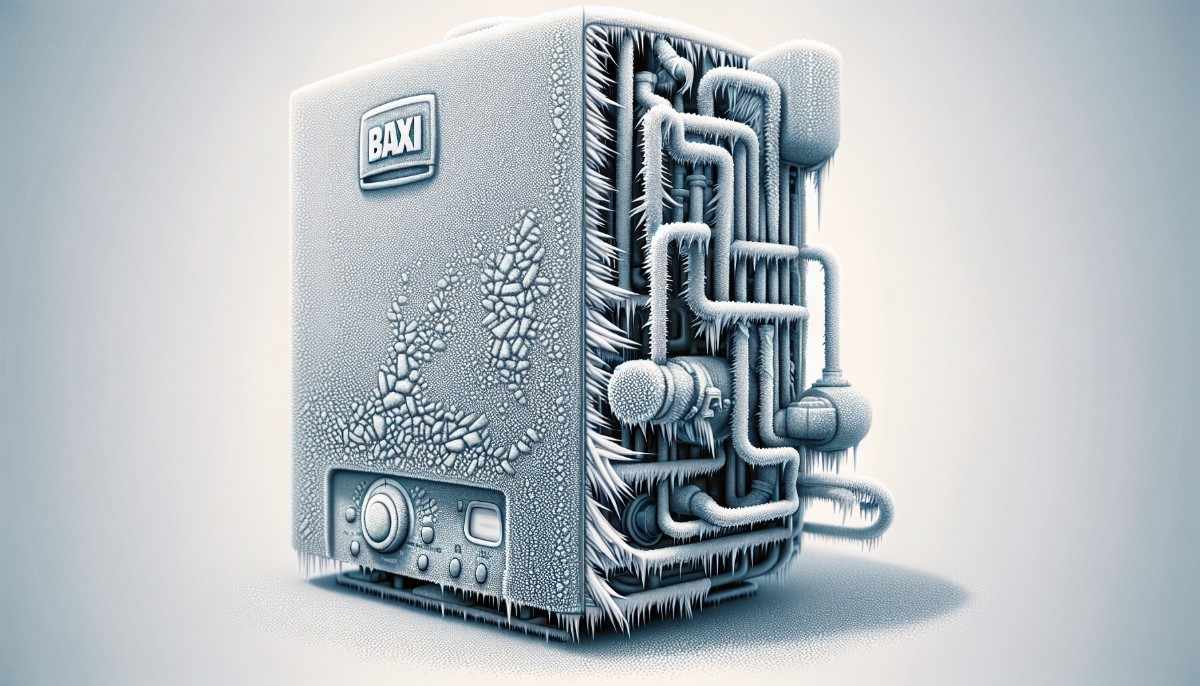

Frozen Condensate Pipe

Another common issue, especially during the colder months, is a frozen condensate pipe. This problem can cause your Baxi boiler to shut down and display error codes such as E133 or E28. A frozen condensate pipe prevents the boiler from igniting by blocking the flow of condensate, which can lead to no heating or hot water.

Pouring warm water over the pipe to thaw it is one way to rectify this issue. Ensure that the water is warm, not boiling, to avoid damaging the pipe. If you’re uncertain about the process or the issue continues, seeking help from a registered engineer is recommended.

To prevent future freezing, consider insulating the condensate pipe or rerouting it to a less exposed location.

Water Leaking

Water leaks in your Baxi boiler can be a sign of more serious issues, such as broken internal components like the pump seal or pressure valve. Leaks can lead to low boiler pressure and other operational problems, so it’s crucial to address them promptly.

In case of water leakage from your boiler, reaching out to a Gas Safe registered engineer for problem diagnosis and resolution is advised. Attempting to fix a leak yourself is not advised and may void your boiler’s warranty. Professional help ensures that the issue is resolved safely and effectively.

Troubleshooting Ignition Problems

Ignition problems can be particularly frustrating as they often leave you without heating or hot water. Baxi boilers may fail to ignite due to various reasons, including:

- Issues with the gas supply

- Ignition leads

- Electrodes

- Printed circuit board (PCB)

Comprehending these potential triggers is beneficial in troubleshooting and effectively resolving the issue.

A malfunctioning gas valve is a common culprit behind ignition problems. To troubleshoot this issue, follow these steps:

- Ensure that your boiler’s gas supply is active.

- Check for any visible faults or damage to the faulty gas valve. (qualified gas engineers only)

- If the issue persists, it may require professional intervention to diagnose and fix the underlying cause.

Boiler Will Not Ignite

If your Baxi boiler fails to ignite, the first step is to attempt a reset using the reset button on the control panel. This simple action can often resolve minor faults and get your boiler back up and running. However, if the boiler continues to fail to ignite, it may have gone into lockout to prevent damage from more serious issues.

One common reason for ignition failure is a closed gas stopcock. Ensure that the stopcock is fully open to allow gas to flow to the boiler. Additionally, if there are no error codes displayed, it could indicate an underlying electrical fault that requires professional attention.

Persistent ignition issues should not be ignored, as they can lead to more significant problems. Contacting a heating engineer can help you diagnose and fix the issue, ensuring that your boiler operates safely and efficiently.

Pilot Light Issues

Older models of Baxi boilers may have a pilot light that can go out, causing the boiler to stop working. If this happens, consult your boiler’s manual for instructions on how to relight the pilot light. Ensuring that the gas supply is active and resetting the boiler should be your first steps in addressing pilot light issues.

Sometimes, the pilot light may not ignite due to dirt buildup on the ignition electrode. Cleaning the electrode can help, but this should be done by a Gas Safe registered engineer to ensure safety and effectiveness. If the pilot light issues persist, it might indicate a faulty thermocouple that needs professional replacement.

No Hot Water or Heating

Experiencing no hot water or heating can be particularly frustrating and is often a sign of a malfunctioning Baxi boiler. This issue can stem from various problems, including:

- Broken diaphragms

- Airlocks

- Failed valves

- Thermostat issues

- Water pressure problems

- Blockages in the system

Identifying the root cause is essential for effective troubleshooting and repair.

If your boiler seems to be working but there’s no hot water, it could indicate a faulty component such as a diaphragm washer, diverter valve, or a blocked domestic hot water heat exchanger. These issues can prevent hot water from reaching your taps even if the boiler is firing up.

When faced with no hot water or heating, it’s best to call a Gas Safe registered engineer to diagnose and fix the problem. Professional intervention can ensure that all components are functioning correctly and that your boiler is safe and efficient to use.

Faulty Diverter Valve

A faulty diverter valve is a common reason for the lack of hot water in Baxi boilers. This valve directs water to either the heating or the hot water system, and if it becomes worn, stuck, or faulty, it can disrupt the flow of hot water to your taps.

Natural system corrosion or metallic sludge buildup over time can cause a diverter valve to fail. If you suspect a faulty diverter valve, it’s recommended to contact a heating engineer for proper diagnosis and replacement. Regular maintenance and system flushing can help prevent such issues.

Thermostat Issues

A malfunctioning thermostat can prevent your Baxi boiler from providing hot water or heating, resulting in intermittent or no heating. If there are no clear issues with the thermostat, it may need to be replaced, which should be done by a professional.

Consider fitting a room thermostat to save energy and reduce your carbon footprint. This small adjustment can lead to significant energy savings and help maintain a comfortable temperature in your home.

Loud Noises from Your Baxi Boiler

Unusual noises from your Baxi boiler can be alarming and indicate underlying issues. A loud noise may suggest a broken burner or the boiler overheating, while a vibrating noise could be due to loose brackets holding the boiler in place. Addressing these noises promptly can prevent further damage and ensure your boiler operates efficiently.

If your boiler makes a banging noise, try bleeding the radiators and checking that hot water is flowing through them. If the noise persists, it’s best to contact a heating engineer for further inspection and repair.

Kettling

Kettling is a common issue in Baxi boilers, characterised by loud banging or rumbling sounds. This noise is generally caused by the buildup of limescale within the system, leading to overheating. Addressing kettling involves flushing the system to remove limescale and sludge buildup.

Persistent kettling noise should not be ignored, as it can lead to more severe issues if left unaddressed. Regular maintenance and system flushing can help prevent kettling and ensure your boiler operates smoothly.

Air Trapped in System

Trapped air in your Baxi boiler system can cause the following issues:

- Gurgling noises

- Overheating

- Obstructed water flow

- Boiler shutdown

To resolve these issues, you can try bleeding the radiators. This is an effective method for removing trapped air and restoring proper functioning to your boiler system.

Regularly bleeding your radiators can help prevent trapped air and ensure that your boiler and central heating system operate efficiently. If the problem persists, contacting a heating engineer may be necessary to identify and resolve the underlying cause.

Baxi Boiler Error Codes

Grasping the meaning of Baxi boiler error codes is of utmost importance for quick diagnosis and resolution of issues. Error codes are alphanumeric signals displayed on the boiler’s interface, systematically identifying specific problems the system has detected. Recognising these codes can help you take appropriate action and maintain your boiler’s health and efficiency.

Common error codes include 110 for overheating, E168 for electrical issues, and various red and green flashes indicating different faults. Knowing what these codes mean can save you time and prevent further damage to your boiler.

110 Error Code

The 110 error code on a Baxi boiler indicates an overheating issue. When this code appears, it means the system has detected conditions that could lead to overheating, prompting the boiler to shut down for safety.

To address the 110 error code, you can try bleeding the radiators to release any trapped air. If the problem persists, it may indicate a more severe issue such as a blocked heat exchanger, requiring professional intervention.

E168 Error Code

The E168 error code is an indication of electrical issues in Baxi boilers. This code can be triggered by various electrical problems, including power supply disruptions and wiring faults. Since electrical issues can be complex and potentially dangerous, it’s essential to seek professional diagnosis and repair when this error code appears.

Ignoring the E168 error code can lead to more severe problems and potentially damage your boiler’s internal components. A qualified heating engineer can accurately diagnose the issue and ensure that your boiler operates safely and efficiently.

Red and Green Flashes

Red and green flashes on your Baxi boiler typically indicate different states or faults. Red flashes usually signal a fault that needs attention, while green flashes can indicate a reset or power-on state. Understanding these indicators can help you troubleshoot and resolve issues more effectively.

To reset your Baxi boiler, follow these steps:

- Locate the reset button, usually on the control panel.

- Press and hold the reset button for 5-10 seconds until the green light starts flashing.

- Wait for the boiler to reset and check if the fault has cleared.

If the problem persists, it may require professional inspection and repair.

Boiler Keeps Switching Off

A Baxi boiler that keeps switching off can be frustrating and indicate several potential issues. Some common culprits include:

- Power supply interruptions

- Gas supply issues

- Pressure discrepancies

- Internal component faults

Comprehending these factors is beneficial for effective identification and resolution of the problem.

If your boiler is repeatedly turning on and off, it could be due to overheating, low water pressure, or a malfunctioning thermostat or valve. Addressing these issues promptly can prevent further damage and ensure that your boiler operates efficiently.

Overheating Issues

Overheating issues in Baxi boilers can result from:

- A buildup of limescale and sludge, leading to a kettling noise in the heat exchanger

- A broken or blocked heat exchanger, which can cause the boiler to shut down due to overheating

- Persistent error code 110, even after bleeding radiators, suggesting checking for any blockages in the system.

If your boiler frequently overheats, it’s essential to address the issue promptly to prevent further damage. Regular maintenance and system flushing can help prevent overheating and ensure that your boiler operates efficiently.

Water Flow Problems

Water flow problems can cause your Baxi boiler to shut off unexpectedly. Blocked valves or a malfunctioning pump can impede water flow, leading to the system shutting down. When no error code is displayed, it suggests an underlying problem not immediately identifiable by the boiler’s diagnostic system.

Addressing water flow problems promptly is essential to prevent further damage to your boiler. If you suspect a blocked valve or malfunctioning pump, it’s best to contact a heating engineer for proper diagnosis and repair.

When to Call a Gas Safe Registered Engineer

Recognising the right time to seek assistance from a Gas Safe registered engineer is key to maintaining the safe and efficient operation of your Baxi boiler. Persistent problems and safety concerns are two primary reasons to seek professional help. When a boiler does not display an error code, it is important to seek professional insight for safe and appropriate diagnosis of the issues. This will help ensure safety and prevent any potential hazards.

Gas Safe engineers have the expertise to diagnose complex problems and provide expert advice. Only a Gas Safe registered engineer is legally qualified to remove your boiler’s casing and perform necessary repairs. Finding a reliable, qualified heating engineer to fix your boiler as soon as possible is essential for maintaining your boiler’s efficiency and safety.

Persistent Problems

If you experience recurring issues with your Baxi boiler, even after initial troubleshooting checks, it’s time to call a Gas Safe engineer. Persistent problems suggest underlying issues that require professional inspection and repair. Regular maintenance by a Gas Safe engineer can help prevent these problems and ensure your boiler operates efficiently.

For issues like low boiler pressure, it’s advisable to consult a professional unless you have the manual and feel confident resolving the issue yourself. Professional intervention ensures that all components are functioning correctly and that your boiler is safe to use.

Safety Concerns

Safety concerns, such as gas leaks or electrical issues, require immediate attention from a Gas Safe registered engineer. Employing a Gas Safe engineer for inspection, repair, or maintenance ensures compliance with legal safety standards and maintains the warranty. Gas Safe engineers are necessary for identifying and safely addressing gas leaks or other hazardous conditions.

A sudden drop in pressure might indicate a leak in the system or an air pressure switch fault, requiring immediate attention from a Gas Safe registered engineer. In such cases, turn off the water supply and contact a professional to ensure your safety and prevent further damage.

Maintenance Tips for Preventing Baxi Boiler Issues

Frequent maintenance plays a significant role in averting common Baxi boiler problems and guaranteeing efficient functioning. Annual servicing by a qualified heating engineer is recommended to keep the warranty valid and maintain the boiler’s efficiency. Keeping your boiler clean and ensuring air vents, grilles, and flues are free from blockages also contribute to its longevity.

Leaving clearances around the boiler as recommended by the manufacturer ensures safe access and servicing. Regular maintenance and timely repairs can prevent significant problems and keep your boiler running smoothly.

Annual Servicing

Yearly servicing is of critical importance to sustain the efficiency of your Baxi boiler. Regular checks on all boiler components ensure they are working correctly and can prevent breakdowns. Full strip-down servicing often involves cleaning key parts such as the heat exchanger and replacing the seals.

A qualified heating engineer should perform annual servicing to guarantee a high standard of work and safety. Ensuring your engineer is Gas Safe registered provides peace of mind that the servicing is done correctly and safely.

DIY Maintenance Tips

Homeowners can perform some basic maintenance tasks to keep their Baxi boilers running efficiently. Setting the timer to ensure the boiler only works when needed can save on energy costs. Turning down the room thermostat by one degree at a time can help find a comfortable yet energy-saving temperature.

Lagging your hot water tank and insulating the surrounding pipes can further reduce energy costs. Regular maintenance to remove debris and limescale buildup can prevent overheating and ensure your boiler operates smoothly.

Summary

In summary, understanding common Baxi boiler issues and knowing how to address them can save you time, money, and a lot of frustration. Regular maintenance, timely repairs, and professional intervention when necessary are key to ensuring your boiler operates efficiently. From low boiler pressure to frozen condensate pipes and water leaks, being proactive about these issues can prevent significant disruptions to your heating and hot water supply.

By following the tips and guidance provided in this guide, you’ll be better equipped to handle minor issues on your own and know when to call in a Gas Safe registered engineer for more complex problems. Keep your home warm and your boiler running smoothly all year round by staying informed and taking action when needed.

Frequently Asked Questions

What should I do if my Baxi boiler shows low boiler pressure?

If your Baxi boiler shows low boiler pressure, check the pressure gauge. If it’s below 1.0 bar, you can try re-pressurising the boiler according to the manual or seek help from a heating engineer.

How can I prevent my condensate pipe from freezing?

To prevent your condensate pipe from freezing, insulate the pipe, reroute it to a less exposed location, and consider thawing a frozen pipe with warm water during cold weather.

What does the 110 error code on my Baxi boiler mean?

The 110 error code on your Baxi boiler means there’s an overheating issue. You can attempt to release trapped air by bleeding the radiators, but if the problem persists, it’s best to consult a qualified heating engineer.

When should I call a Gas Safe registered engineer?

You should call a Gas Safe registered engineer for persistent problems, safety concerns such as gas leaks or electrical issues, and for regular annual servicing to maintain your boiler’s efficiency and safety. Regular maintenance ensures optimum safety and performance for your boiler.

How often should I have my Baxi boiler serviced?

You should have your Baxi boiler serviced annually by a qualified heating engineer to maintain efficiency, prevent breakdowns, and keep the warranty valid. Regular servicing is crucial for ensuring optimal performance.

Available 24/7, 365 days

City & Guilds trained plumbers

Friendly and helpful service

Fully qualified and insured engineers

Available round the clock support

Ability to deal with any brand or type

Reach us 24/7, 365 days

We’ll get to you within an hour

Repair and install a variety of heating systems